The cartridge in a turntable is the source of all the sound that is heard. Therefore, its geometry and material design are crucial to the overall performance of the system.

Wilson Benesch developed its first cartridge systems in the early 1990s in co-operation with Benz-Micro. Wilson Benesch designed and manufactured the world's first carbon fibre cartridge bodies and headshells. Benz-Micro in turn assembled the generator to complete three pickup options, the ply, the carbon and the analogue pickup. Much of the research that went into the development of these cartridges has been incorporated into the modern era of cartridge design, which is now reflected in the TESSELLATE Ti cartridges.

TECHNOLOGY

Innovative geometric optimisation

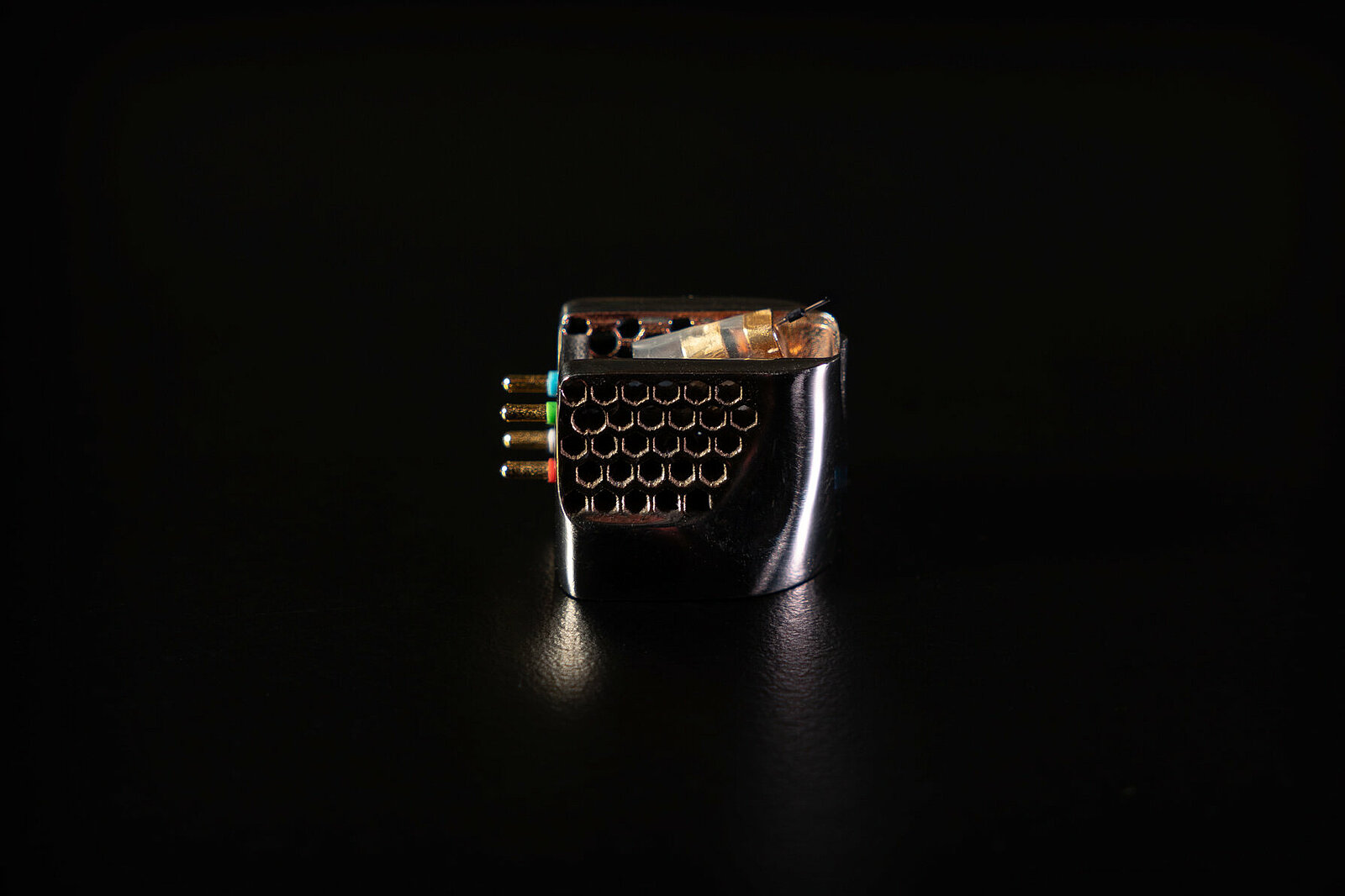

The TESSELLATE Ti cartridges represent the pinnacle of geometric optimisation of cartridge structures. Developed in collaboration with Renishaw PLC and the University of Sheffield, the TESSELLATE Ti cartridge body is manufactured using the latest 3D additive manufacturing technology. The additive manufacturing technology of selective laser sintering (SLS) uses multiple high-power lasers to weld titanium particles together layer by layer to construct a one-piece cartridge body. There is no material redundancy, resulting in a structure that is completely free of unnecessary mass. The unique crystal structure of the material used allows for internal damping that was previously unrivalled.

Semi-open construction

The semi-open design of the headshell is based on the research results gained during the development of the Ply, Carbon and Analogue pickups. During this development, Wilson Benesch realised that a curved headshell surface could achieve considerable sonic advantages for the pickup. The curved geometry increases rigidity and eliminates reflective surfaces, thereby avoiding resonances. The TESSELLATE Ti pickup adopts this semi-open structure and thus achieves maximum rigidity, minimum mass with maximum damping and reduces reflective surfaces to a minimum.

Hybrid cantilever

The TESSELLATE Ti cartridge features an innovative hybrid cantilever design that combines advanced stylus cantilever with unidirectional (U.D.) carbon fibre damping. This results in improved tracking due to reduced resonance. The unidirectional carbon fibre adds virtually no additional mass, but when placed in the centre of the carrier in an offset asymmetrical position, provides a significant gain in stiffness and damping.

The hybrid needle carrier is available in a variety of materials, including boron, sapphire and diamond. Each material offers unique properties that contribute to the overall performance and sound quality of the cartridge

SPEZIFICATIONS

| TESSELLATE Ti-B | TESSELLATE Ti-S | TESSELLATE Ti-D | |

|---|---|---|---|

| Hybrid cantilever | Boron / carbon fibre damping ring | Sapphire / carbon fibre damping ring | Diamond / carbon fibre damping ring |

| Stylus | elliptical | Micro Ridge | Micro Ridge |

| Stylus tip radius | 5x150uM | 5x80uM | 5x80uM |

| VTA | 20 degrees | 20 degrees | 20 degrees |

| Coil | Pure iron square coil | Pure iron square coil | Pure iron square coil |

| Cartridge body & headshell | SLS 3D additively manufactured titanium structure, with tessellated semi-open geometry | ||

| Weight | 17.1g | 17.1g | 17.1g |

| Output voltage | 0,32mV @ 3,54CM/S | 0,35mV @ 3,54CM/S | 0,35mV @ 3,54CM/S |

| Internal impedance | 6 Ohms | 6 Ohms | 6 Ohms |

| Frequency response (+/- 1dB) | 20-25,000 Hz | 20-30,000 Hz | 20-32,000 Hz |

| Dynamic compliance | 12uM/mN | 15uM/mN | 15uM/mN |

| Channel balance | <0,5 dB | <0,5 dB | <0,5 dB |

| Recommended loading | 200-470 Ohms | 100-330 Ohms | 100-330 Ohms |

| Recommended tracking force | 1.1-1.4g | 1.1-1.4g | 1.1-1.4g |

| Recommended tonearm mass | medium | medium | medium |

| Ausführungen / Optionen | Standard Matt Titanium or upgraded Polished Gold and Polished Silver | ||